Evaporative cooling and “drift”

Air conditioning of large buildings is accomplished by transferring the hot air to water, which is then cooled by evaporation in a rooftop cooling tower. Makeup water is used to replenish the water lost by evaporation. But the need for rooftop cooling towers comes with a serious, albeit very small, risk of casting off atomized water particles. This is a phenomenon called “drift”. It causes as much as five percent of evaporated water loss from cooling towers.

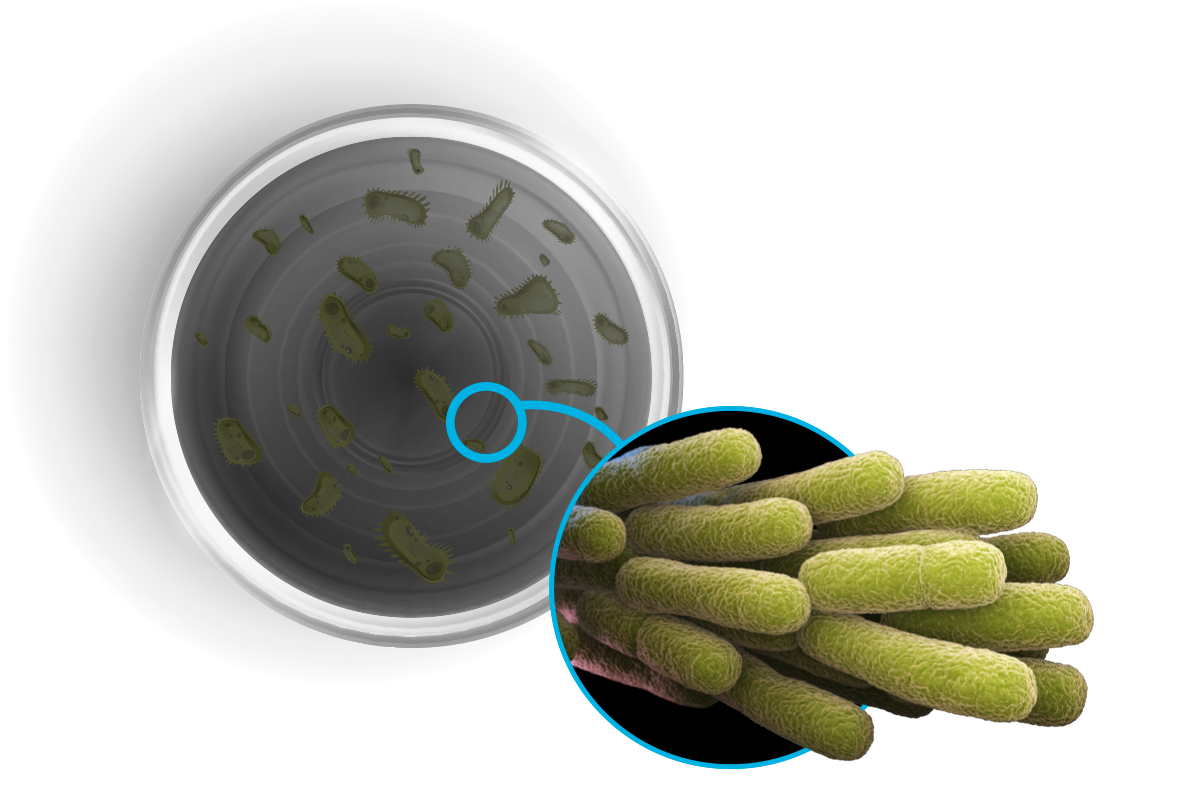

Fouled water can contain high concentrations of bacterial contaminants and some can be deadly. The most infamous example of “drift” is the 1976 Legionnaires’ Disease outbreak that gave a particularly nasty bacteria its name:

Legionella.

Is all bacteria in cooling tower water dangerous?

Legionella is an example of a dangerous, disease-causing pathogen, but not all bacteria are similarly deadly. Many of the problems building engineers experience with bacteria in cooling water have to do with nuisance organisms. These don’t cause disease to people when aerosolized, but they can cause a big mess in the cooling tower and its associated supply lines.

That’s why the goal with cooling tower biocides isn’t to make the water sterile; it’s to bring the nuisance organisms to manageable levels that won’t foul the cooling tower’s mechanical systems and require maintenance, downtime or additional resources for remediation.

Why use bromine?

BromMax® is a source of bromine. This is an oxidizing agent that uses reactive chemistry to kill bacteria. Non-oxidizing agents are toxic to bacteria but disrupt specific metabolic pathways. Oxidizing agents are more indiscriminate – think of them as “chemical incinerators.” These agents are more adept at controlling the “gunk” in cooling towers as they destroy all forms of microbiological contamination.

Traditionally, bromine has been used in cooling towers as bromine tablets. These are introduced to specialized feeding devices through which make-up water or recirculating cooling water flows. The tablets partially dissolve and continuously release bromine. But the most popular way to fight cooling tower water fouling is with a stabilized liquid bromine formula.

The beauty of treating cooling tower water with a stabilized form of liquid bromine is that it eliminates the need to treat the water continuously, does not require special feed equipment and has complete water solubility to ensure its fast distribution throughout the cooling water system.

Both formulas are biocides that prevent the proliferation of waterborne microorganisms in cooling water treatment systems. These liquid bromine biocides are the best way to implement an ongoing biocontrol program to prevent and eliminate damaging microorganisms from cooling water treatment systems.

BromMax® formulations are effective agents for controlling algae, bacteria, and slime in evaporative condensing equipment associated with air-conditioning systems.

Our strongest formula – BromMax® 10.2 – is compatible with all commonly-used construction materials in cooling systems and works exceptionally well in warmer climates where higher concentrations of biocides are needed. BromMax® 7.1 is the most frequently used liquid bromine biocide product, created with the same innovative process used in the 10.2 formulation but with a lower concentration.

The goal with cooling tower biocides isn’t to make the water sterile; it’s to bring nuisance organisms to manageable levels that won’t foul the cooling tower’s mechanical systems and will require maintenance, downtime or additional resources for remediation.”

Whatever you call the goop that collects in your cooling tower, BromMax® products bring the power of stabilized liquid bromine to the cooling tower and prevent the harmful, ugly gunk from making a big mess of your cooling operation.